Feedgy Digital

Master Your Solar Assets with Digital

- Are you curious to discover if your solar operation is operating at peak performance? Perhaps you're ondering how much potentiel gain awaits you or how to achieve it and at what cost ?

- Welcome to the digital realm Feegdy!

- Do you want to know the solution to achieve it and how much it costs?

- Welcome to the digital world of Feedgy!

Harness the power of digital technology for your solar operations with artificial intelligence, Feedgy helps you identify untapped sources of kWh and potential production gains. Whether you seek to optimize performance, maximize efficiency, or uncover hidden opportunities, our digital solutions actionable insights to propel your solar assets to new heights.

Most photovoltaic monitoring solutions are not precise enough to detect performance drops in a solar plant, let alone identify the cause. Traditional performance tools, on the other hand, are designed for new plants and do not rely on historical data from operating plants to establish a maximized production model.

Consequently, operators often find themselves solely maintenance visits. This dependency can result in extended periods without corrective actions, leading to unquantified financial losses. Additionally, O&M teams, in turn, rely on manufacturer's monitoring tools and physical field visits.

The solar sector is gradually benefiting from the latest digital technological advancements that can assist operators in the operation of their plants:

- Optimize existing installations as the development of new surfaces becomes increasingly complex and costly.

- Maximize profitability by reducing the levelized cost of electricity (LCOE).

- Gain visibility into assets for better short and medium-term management.

- Facilitate day-to-day O&M activities.

However, it is challenging to find a single tool, tailored to solar, that addresses all of these challenges and serves as a decision-making tool.

That's why Feedgy has developed a new innovative method, based on the analysis of actual production data using unique algorithms, to accurately identify deteriorations and optimize maintenance and operational costs of solar plants.

e-Score+: An Enabler of Repowering Opportunities for Your Park

A quick audit tool to quantify losses in an existing installation and identify the potential of the plant once optimized.

A prerequisite for all interventions, and based on only a few key pieces of information, e-Score+ allows you to determine the technical and financial interest of Repowering. This tool provides you with an instant answer on the potential of an installation and its performance gains.

A Catalyst for Repowering Opportunities in Your Park

Historical performance and losses by plant

Simulation and projection of gains

Calculation of freed-up space

REX (Return on Experience) in the Service of Repowering

analyzing the repowering potential of a plant based on its actual production

REAL-TIME ANALYSIS

to quantify installation losses and identify potential

LONG-TERM PROJECTION

of projection for the plant in its current state with Repowering

COMPATIBILITY WITH ALL TECHNOLOGIES

of models and inverters can be used by the system

Re-Act: a real decision-making tool

Depending on the specific features of each photovoltaic plant, our AI (Artificial Intelligence) algorithms will take into account actual and historical production data, as well as meteorological and environmental data, to automatically detect and locate faults.

Once compared with the prediction of energy production via the creation of a digital twin, Re-Act makes it possible to quantify the energy and financial losses associated with each type of fault.

With our expertise in maintenance, Re-Act is able to recommend appropriate actions to increase productivity and extend plant life.

The Power of AI Applied to Solar Park Management

Identification of faults and losses

Estimation of financial projections

INCREASED MODEL ACCURACY

production forecast accuracy (10% improvement over the state of the art)

REAL-TIME FAULT DETECTION

to quantify installation losses and identify potential

INTEROPERABILITY

for the integration of raw data into the solution

DETECTION OF INVISIBLE FAULTS

detectable flaws

Re-Veal: The Most Advanced Performance Audit on the Market

The Re-Veal performance audit allows for a deeper exploration of our innovative algorithms through a dynamic view of production since commissioning.

The historical evolution of the plant enables the detection of a greater number of faults and a more extensive calculation of the plant's performance indicators.

Re-Veal is a tool aimed at ensuring investor peace of mind in Repowering implementation. The use of 15 years of meteorological data allows for the integration of different scenarios into the Business Plan and thus avoids unpleasant surprises in the future.

The Most Precise Performance Audit in the Market

Quantification of historical losses and financial risks

Revealing the invisible through our analysis algorithms

Proposed actions to increase production

PRECISE CALCULATION OF PERFORMANCE INDICATORS

Calculated on different elements of the plant and at the overall level

DYNAMIC VIEW OF PRODUCTION

of analysis with minute granularity (15-10-1 minute) of data

INTEGRATION OF HISTORICAL WEATHER CONDITIONS

of weather data to allow scenario calculations (P50, P90)

DETECTION OF INVISIBLE FAULTS

11 detectable faults, thanks to the analysis of production curve evolution Going Further

Going further

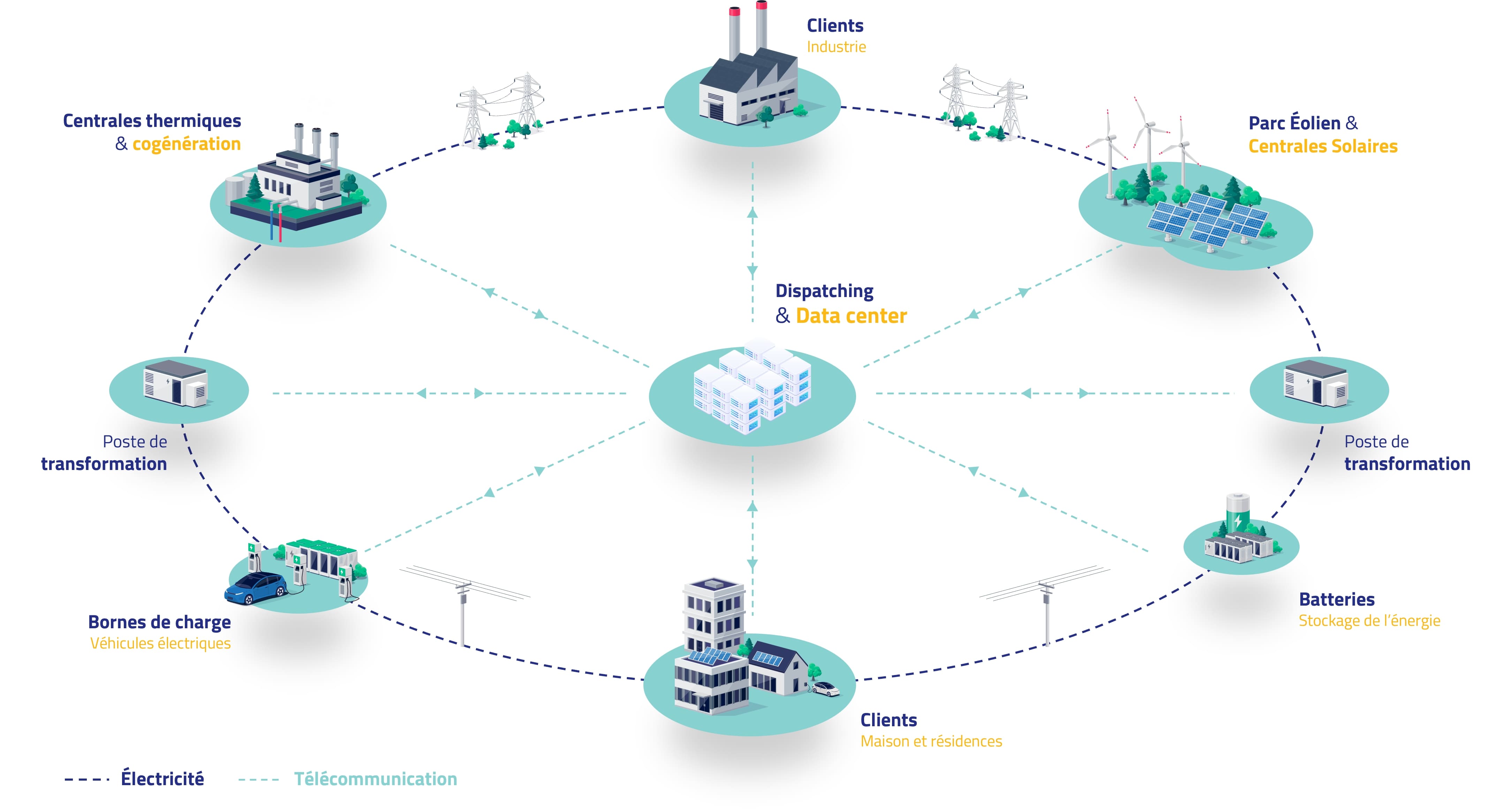

We are also preparing the future of your plant so that it can integrate into the new decentralized energy network model and the establishment of local 'microgrids' designed to meet the specific needs of regions. Intelligent network management requires a more agile and responsive infrastructure involving data communication on energy availability and demand. The proliferation of energy sources, renewable intermittency, and new forms of electricity consumption (such as electric vehicles) require a perfect understanding of the state of the network to balance.

Feedgy is working on a portfolio of digital projects through which your installations will be ready to interact with the network of tomorrow:

- Predictive maintenance

- Fault detection and diagnosis

- Performance monitoring

- Production prediction

- Optimization of electricity sales

- Management of collective self-consumption